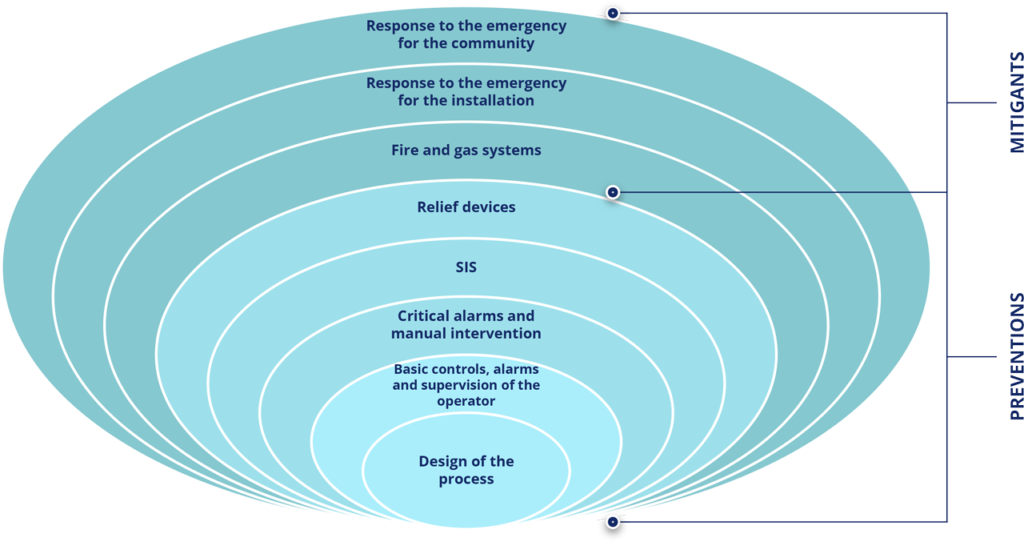

In BFC Consulting we are specialists in management processes for the analysis, design, validation and management of the Independent Protection Layers (IPLs) for complying with the criteria of IEC 61511.

The characteristics that the independent protection layers (IPL) must comply with under IEC 61511 are the following:

Specific: Must be designed to be a safeguard.

Auditable: Must be examined and proved routinely.

Independent: Should not be related to any other IPL or to the event initiator.

Reliable/Effective: Must typically have a probability of failure less than 0.1.

01

BASIC PROCESS CONTROL SYSTEM (BPCS)

02

ALARMS MANAGEMENT

03

SAFETY INSTRUMENTED SYSTEMS (SIS / SPPE)

04

RELIEF/BURNER DEVICES

05

FIRE AND GAS SYSTEMS

06

FIREFIGHTING SYSTEMS

07

FIREWALLS

08

EMERGENCY RESPONSE PLAN (ERP)

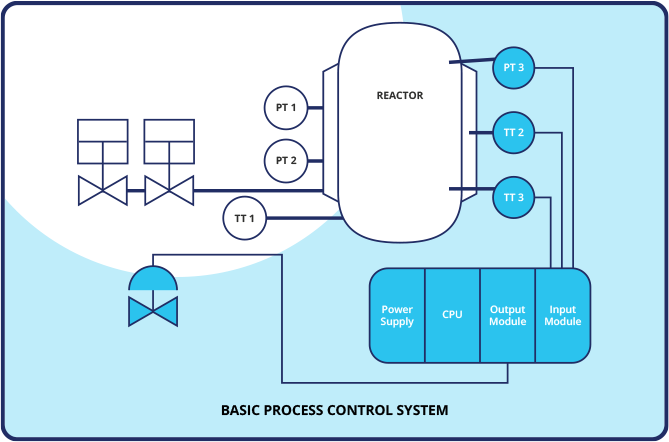

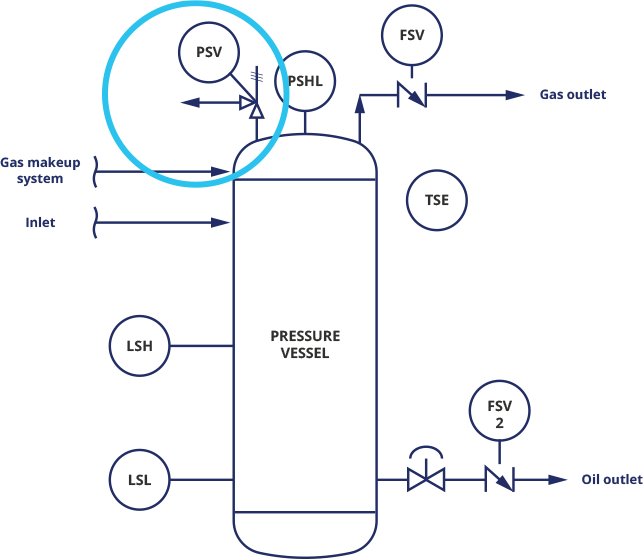

The BPCS responds to input signals of the process, its associated equipment, other programmable systems and/or an operator and generates output signals that make the process and its associated equipment function in the desired manner.

Maintain the process variables within the limits of safety (pressure, temperature, level, etc.).

In BFC we verify compliance with the clauses defined in the IEC-61511 to establish the level of reduction of assigned risk and the design parameters are modeled through a specialized dynamic simulation software for the evaluation of risk scenarios that involve the performance of the BPCS.

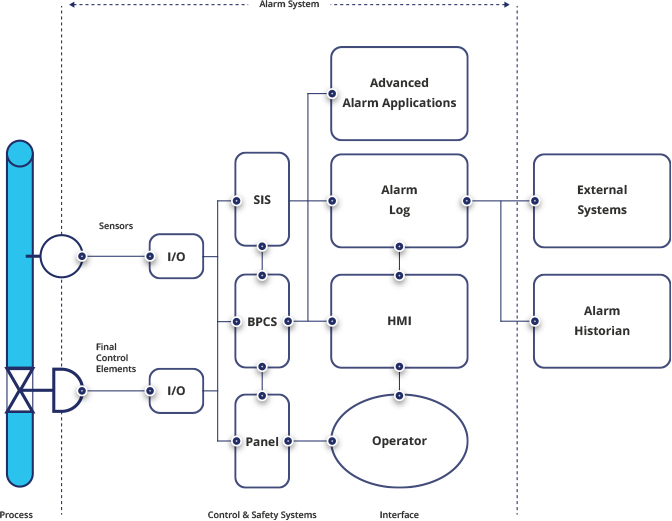

We will develop a detailed analysis to determine the criticality and effectiveness of the BPCS, SIS, F&GS alarms and the technical information to validate the timely response action of the operator applying the principal activities and requirements of the Alarms Management Life Cycle during the stages of evaluation, development, design, installation and management of an Alarm System in the industrial processes as established in the IEC-62682/ISA 18.2.

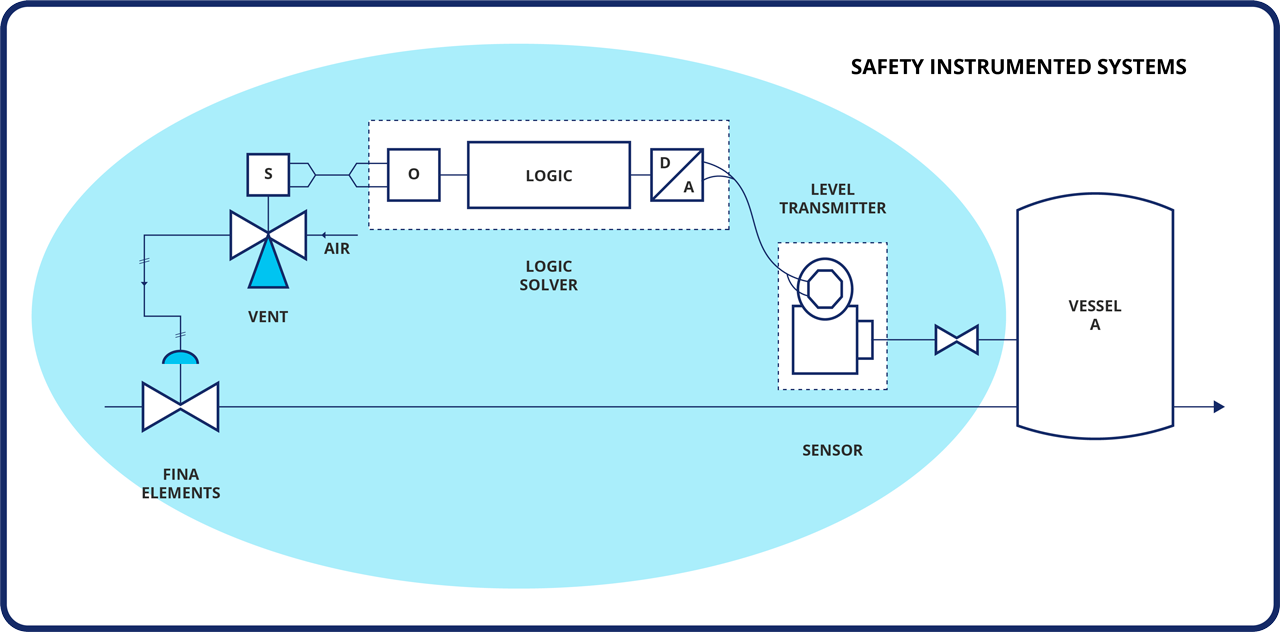

We develop the different activities in each stage of the Life Cycle of the Functional Safety of the Safety Integrated Systems (SIS) regarding compliance with the requirements established in IEC-61508 / IEC-61511 / ISA 81.00.01.

It is vitally important that the mechanical pressure-relieving devices be considered correctly in the context of the independent protection layers in order to assign an appropriate risk reduction value; our certified specialists evaluate through the use of dynamic simulation software their correct design, selection, validation and performance according to compliance with the regulatory framework:

In BFC we do the analysis, design and validation of the Fire and Gas System (F&GS) defining its philosophy and specification in function of the life cycle.

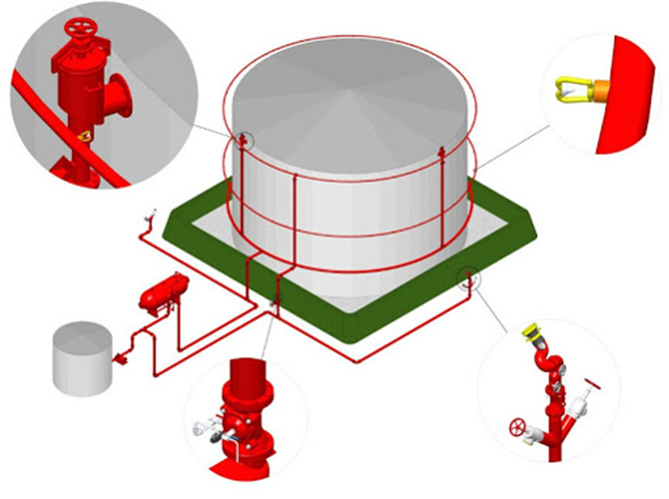

In BFC we do different specialized studies of the Firefighting Protection System for technical personnel certified by NFPA to evaluate and validate the performance of the system, including the Hydraulic Analysis and the performance tests of the firefighting pumps and associated mitigation equipment of the firefighting water network and the sprinkler systems (flow, pressure, velocity, etc.) ensuring regulatory compliance referenced in:

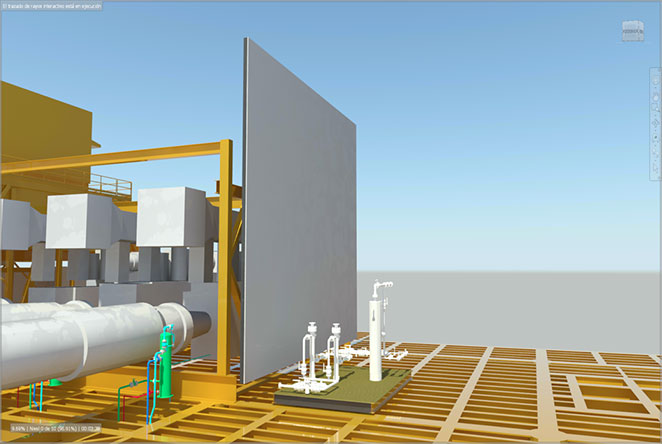

In BFC we determine the design requirements used for the structural analysis of the firewalls in function of the expected consequences of an undesirable event ensuring the safety of vulnerable personnel and equipment based on the classification of areas to protect.

ISO 13702: Petroleum and Natural Gas Industries/Control and Mitigation of Fires and Explosions on Offshore Production Installations/Requirements and Guidelines First Edition (Petroleum and Natural Gas Industries/Control and Mitigation of Fires and Explosions on Offshore Production Installations/Requirements and Guidelines First Edition).

API RP 752. Management of Hazards Associated with Location of Process Plant Buildings.

ISO-22899-1. Determination of the resistance to jet fires of passive fire protection materials – Part 1: General requirements (Determination of the resistance to jet fires of passive fire protection materials – Part 1: General requirements).

Although the evacuation plans are not represented by physical mitigations, but by a group of specific procedures, these may be considered as an authentic protection layer, because in absence of a specific protocol there is a high level of risk for the people exposed in an installation. The evacuation signals are normally announced by the sound of sirens and the use of means of transport specifically used for that purpose.

In BFC we develop the ERP from the protection layer point of view based on an internal organizational structure that, using expert personnel and specific internal means, urgently intervenes to mitigate the harmful effects of hazardous events inside the plant and impedes the possible propagation of those effects outside the limits of the installation.